Product Description

Integrated Closed Loop Stepper Motors are high-performance drive solutions that integrate high-precision stepper motors with closed-loop control systems, and are widely used in industrial automation, 3D printing, CNC equipment and other fields.

advantages

High-Precision Positioning

Built-in high-resolution encoder enables precise micro-step feedback, achieving positioning accuracy down to the micrometer level.

Smooth Operation and Low Vibration

Closed-loop control automatically adjusts current, achieving smooth acceleration and deceleration and low-vibration operation, reducing mechanical wear.

High Dynamic Response

Integrated controller supports fast response and precise speed control, suitable for high-speed machining and precision manufacturing scenarios.

Flexible Compatibility

Supports various mounting interfaces and motor specifications, facilitating integration with existing systems.

why choose us

Complete Industrial Chain: Owns hardware, electronics, electromechanical, and new energy factories, enabling one-stop production across the entire process.

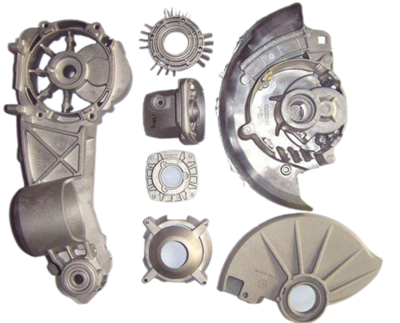

Advanced Equipment: Laser cutting, bending, stamping, die casting, CNC, and other equipment meet the needs of high-precision machining of multiple materials.

High-Precision Machining: Five-axis/six-axis CNC lathes achieve an accuracy of 0.001 mm, with a monthly production capacity of 200,000 pieces.

Strict Quality Control: Full-process quality management, equipped with CCD, 3D measurement, precision height gauges, and other testing equipment.

FAQ

Q: What voltages and drive modes are supported?

A: Compatible with various standard stepper drives and voltage specifications, facilitating direct replacement or integration.

Q: Can you provide customized motors?

A: We can customize sizes, torque, or interfaces according to customer needs. Contact us for solutions.

Q: What are typical application scenarios?

A: Suitable for industrial automation, CNC machine tools, robots, medical equipment, and precision instruments.

Q: How do you guarantee accuracy and reliability?

A: Using high-precision encoders, closed-loop control algorithms, and high-quality materials ensures long-term stable operation.

Q: What is the typical production cycle?

A: Standard batches typically take 2–5 weeks, depending on order quantity and customization requirements.

Q: What about after-sales service?

A: We offer returns and exchanges for quality issues and technical support, and can provide customized solutions for complex applications.

Hot Tags: integrated closed loop stepper motors, China integrated closed loop stepper motors manufacturers, suppliers, factory, copper pcb sheet, stainless steel parts manufacturing, stepper motors, cnc services, cnc machining aluminum parts, cnc metal turning