Why Choose Us

Professional Team

Our company has a strong R&D and production management team, equipped with advanced production machinery and highly precise testing instruments.

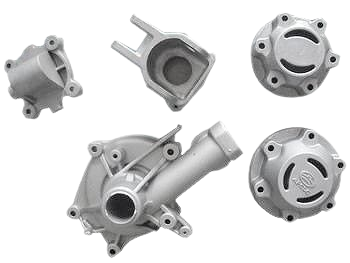

Multiple Business Products

The company operates a series of products including automotive components,3C (Computer, Communication, Consumer Electronics) product casings etc.

High Professional Level

Vietnam Atlantic Industrial Co., Ltd. is a company that integrates research and development, design, production, processing, and sales.

Quality Control Measures

The factory is equipped with comprehensive inspection equipment including CCD inspection equipment, 2.5D microscope, 3D etc.

Product Applications Cover a Wide Range

Including automotive, smartphones, tablets, televisions, smart home devices, medical equipment, industrial automation control, etc.

Good Sales

Products are exported to Japan, the United States, Germany, Southeast Asia etc.

What is Copper PCB Sheet

A Copper PCB Sheet, also known as a Copper-Clad Laminate or Copper-Clad Board, is a type of Printed Circuit Board (PCB) that features a layer of copper adhered to a non-conductive substrate material. This copper layer serves as the conductive pathway for electrical signals within the circuit.

Related Product

Looking for Rogers PCB fabrication services? You've come to the right place. At Atlantic, we specialize in providing top-notch PCB fabrication using Rogers materials, renowned for their exceptional performance and reliability in demanding applications.

FR-4 is the most commonly used material for rigid PCBs. You might need FR-4 printed circuit boards, but perhaps you're not quite sure. Let's explore when FR-4 PCBs are the right choice by comparing them with ceramic PCBs and metal-core PCBs (MCPCBs).

Aluminum PCB Fabrication service , also known as Metal Core PCBs (MCPCBs), are a popular choice for applications requiring superior heat dissipation and high durability. These boards are especially favored in industries like LED lighting, power converters, automotive, and other high-power electronics.

Copper PCB sheets are essential in the manufacture of high-performance printed circuit boards (PCBs). These sheets are known for their excellent electrical conductivity, thermal management, and reliability, making them a preferred choice in various high-tech applications.

From prototype to manufacturing, Atlantic has you covered for all your flexible PCB and rigid-flex PCB needs. Our extensive knowledge and experience in manufacturing flexible printed circuit boards give us a competitive edge in the PCB industry. We require no minimum order quantities and always promise competitive prices and unbeatable customer service.

Advantages Of Copper PCB Sheets

High electrical conductivity

Copper is an excellent conductor of electricity, ensuring efficient and reliable signal transmission across the PCB.

Superior thermal management

Copper's high thermal conductivity allows for effective heat dissipation, reducing the risk of overheating and improving the overall lifespan of electronic components.

Durability

Copper PCBs are robust and can withstand significant mechanical stress, making them suitable for demanding applications.

Versatility

Copper PCBs can be used in a wide range of applications, from consumer electronics to industrial equipment.

High reliability

Thick copper PCB adopts ultra-thick copper foil as the conductive layer, which has high conductivity and low resistivity to ensure the stability and reliability of the circuit.

Strong anti-interference ability

With strong anti-electromagnetic interference capability, it can effectively inhibit the interference of electromagnetic wave and ensure the stability of the circuit.

High mechanical strength

Due to the use of ultra-thick copper foil as the conductive layer, it has high mechanical strength and can withstand greater pressure and impact.

High corrosion resistance

It has strong corrosion resistance and is able to resist the erosion of many chemicals.

Fast signal transmission

Adopting extra-thick copper foil as the conductive layer, it has low resistivity and excellent conductivity, and is able to provide high-speed signal transmission.

Good electromagnetic shielding effect

With strong electromagnetic shielding effect, it can effectively reduce the interference of electromagnetic wave.

Application of Copper PCB Sheets

Consumer electronics

Smartphones, tablets, and other portable devices rely on copper PCBs for their compact and efficient design.

Industrial equipment

Copper PCBs are used in machinery and equipment that require high reliability and performance.

Automotive

Automotive electronics, including engine control units and infotainment systems, utilize copper PCBs for their durability and excellent performance.

Medical devices

High-precision medical equipment depends on copper PCBs for accurate and reliable operation.

Types of of Copper PCB Sheets

Single Panel: Parts are concentrated on one side and wires are concentrated on the other side. Since the wires are only present on one of the sides, there are many limitations in designing the circuit, so early circuits mostly used this type of board.

Double-sided boards: Both sides are wired, and the wires on both sides are connected through vias. Double-sided boards are twice the size of single-sided boards, and the wiring can be interleaved, making them suitable for more complex circuits.

Multilayer: In order to increase the wiring area, more single-sided or double-sided wiring boards are used, which are glued together by placing an insulating layer between each layer. The number of layers in a multilayer board represents the number of independent wiring layers, usually an even number, and includes the two outermost layers.

Flexible Printed Circuit Board (Flexible PCB): Made of a flexible substrate that can be bent to facilitate the assembly of electrical components. Widely used in aerospace, military, mobile communications and other fields.

Rigid PCB: Made of paper or glass cloth base pre-impregnated with phenolic or epoxy resin, laminated and cured with copper-clad laminate on one or both sides of the surface layer.

Rigid-Flex: Combines the characteristics of rigid and flexible boards to provide greater flexibility and functionality where it is needed.

Performance Parameters of of Copper PCB Sheets

Thermal performance

The thermal performance of copper PCBs is evaluated by thermal cracking time and thermal stress test. Thermal cracking time is a parameter for evaluating the thermal resistance of the boards, while the thermal stress test simulates the extreme conditions of the soldering process, checking whether the boards are subject to thermal stresses due to temperature changes that can damage the structural properties of the material.

Flame retardant performance

Flame retardant performance is evaluated by the UL94 flammability test standard, which is divided into three grades, V-0, V-1 and V-2, of which V-0 grade has the highest flame retardant performance.

Conductivity

Copper PCB boards have excellent conductivity and are able to support high current and high frequency signal transmission, as well as good electrical conductivity and low resistance values.

Heat dissipation performance

The high thermal conductivity of copper enables thick copper PCB boards to effectively carry heat away from the temperature-sensitive components of the PCB, keeping the components in good condition.

Mechanical Strength

Thick copper PCB boards have high mechanical strength, enabling more conductive material to be installed in a smaller space and achieving greater mechanical strength for the connectors.

Material Composition of Copper PCB Boards

Substrate layer: This is the main body of the PCB, usually using glass fiber as the substrate, which provides the mechanical strength and stability of the board.

Copper Foil Layer: The substrate is covered with a layer of copper foil, which acts as a conductor to ensure the electrical conductivity of the circuit board. The thickness of copper foil is usually 1/3OZ, 1/2OZ, 1OZ, etc. Different thicknesses of copper foil vary in conductivity and heat dissipation.

Copper cladding: Copper cladding is used to enhance the conductivity and heat dissipation of the circuit board to avoid damage to the board due to high temperature.

Drilling Layer: When PCB manufacturing, holes need to be drilled to form the required circuit connections.

Printing layer: After drilling, the required circuit patterns are printed onto the PCB by printing technology. In addition, the composition of the PCB board includes some key material properties such as.

Tg value: This is the glass transition temperature, a characteristic of polymers that affects the heat resistance of the board.

PP sheet: Different types of PP sheets have different voids in the center, which affects the dielectric constant of the signal line as it passes through.

RC%: Resin content, i.e., the weight percentage of resin in the sheet, affects the resin's ability to fill the gap between the wires and the thickness of the dielectric layer after the platen is pressed.

RF%: Resin flow rate, which reflects the fluidity of the resin and affects the thickness of the dielectric layer after platen.

YC%: The weight of volatile components lost after drying of semi-cured sheet as a percentage of the original, affecting the quality of the dielectric layer after platen.

DK value and Df: Represent the dielectric constant and dielectric loss angle of the material respectively, which affect the signal propagation speed and loss.

The production process flow of copper PCB board mainly includes the following steps.

PCB Layout: First, the PCB fabrication factory will receive the CAD file from the PCB design company and convert it to a uniform format such as Extended Gerber RS-274X or Gerber X2. Then, the engineers will check whether the PCB layout is correct or not. Then, the engineer will check whether the PCB layout conforms to the production process and whether there are defects and other problems.

Core Board Fabrication: Clean the copper-clad boards, if there is any dust it may cause short or broken circuits. The production of core boards usually starts from the center core board, continuously stacked with copper film and semi-cured sheet, and then fixed.

Inner PCB layout transfer: Cleaned copper-clad boards will be covered with a layer of light-sensitive film on the surface, through the light-sensitive machine with UV lamps on the copper foil on the light-sensitive film, light-transparent film under the light-sensitive film is cured, the light-sensitive film is cured, the light-transparent film under the light-sensitive film is cured. The light-permeable film is cured, and the light-impermeable film is not cured. After the uncured photographic film is cleaned off, the uncured photographic film is cleaned off with lye, and then the unwanted copper foil is etched off with a strong alkali such as NaOH, and finally the cured photographic film is torn off, revealing the desired PCB layout line copper foil.

Core board punching and checking: Core board production success, in the core board on the alignment holes, easy to align with other raw materials. Core board and other layers of PCB pressed together can not be modified, so the inspection is very important, through the machine automatically compared with the PCB layout drawings to see if there is any error.

Laminating: Utilizing the adhesive property of the PP sheet to bond the layers of wiring into a whole. This process needs to consider symmetry to ensure that the board does not bend due to uneven stress during lamination, which affects PCB performance.

Drilling: To produce through holes between the layers of the circuit board to achieve the purpose of connecting the layers.

Chemical copper immersion: After drilling the PCB board in the copper immersion cylinder redox reaction occurs, the formation of copper layer, the holes for metallization, so that the original insulating substrate surface deposited on the copper, to achieve the interlayer electrical connectivity The hole is metallized. Subsequent plate plating, so that the copper in the holes thickened to 5-8um, to prevent the thin copper in the holes in the graphic plating before the oxidation or micro-etching off and leakage of the substrate.

Outer Dry Film and Outer Graphic Plating: The process for the outer dry film is the same as for the inner dry film. Then the outer layer of graphic plating, the hole and line copper layer plating to a certain thickness (20-25um) to meet the final PCB board copper thickness requirements. And will not be used on the board surface of the copper etching off, revealing the useful line graphics.

Soldermask: The final soldermask treatment to complete the production of PCB boards.

Our Factory

Vietnam Atlantic Industrial Co., Ltd. is a company that integrates research and development, design, production, processing, and sales Our company has a strong R&D and production management team, equipped with advanced production machinery and highly precise testing instruments.We have earned industry recognition and trust by consistently delivering safe, reliable, and of the highest quality products to our customers.

Our company owns its hardware factory, electronics factory, mechatronics factory, and new energy factory. Additionally, we have a dedicated professional team focused on solving a variety of challenges. We are committed to providing end-to-end services to our customers, offering a comprehensive range of products and solutions.

The company operates a series of products including automotive components,3C (Computer, Communication, Consumer Electronics) product casings,communication equipment enclosures ,LED products, equipment enclosures,smart home products, and machined products.

FAQ

Hot Tags: copper pcb sheet, China copper pcb sheet manufacturers, suppliers, factory, cnc turning aluminum parts manufacturing, stepper motors, integrated servo motors, single sided pcb assembly, cnc alloy steel, pcbs for consumer electronics